Blog

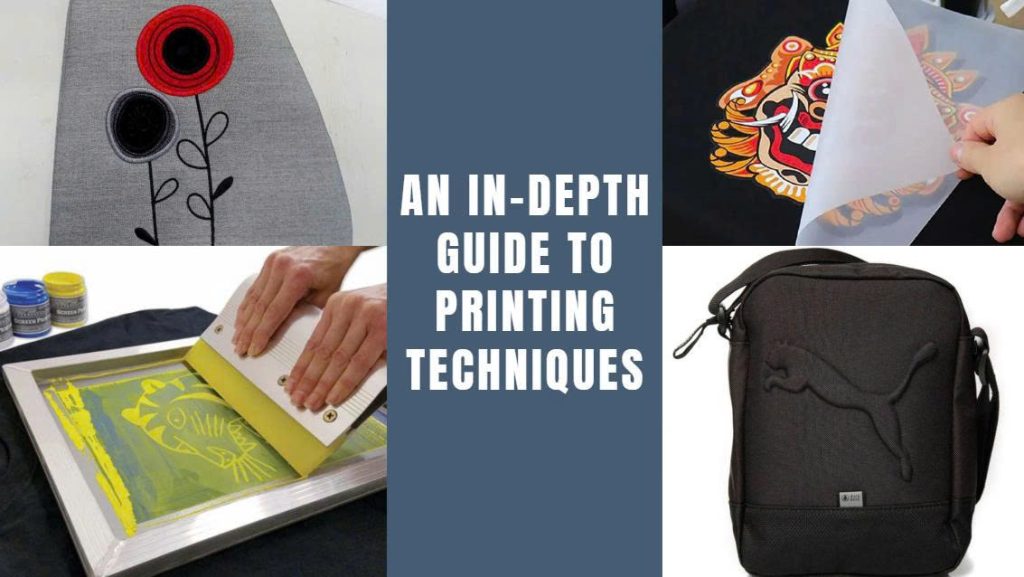

MASTERING BRANDING: AN IN-DEPTH GUIDE TO PRINTING TECHNIQUES

1. SCREEN PRINTING

How it works

Screen printing uses a stencil (screen) to layer ink onto a surface. Each color requires a separate screen, resulting in vibrant and durable prints.

Best for

Companies that need bulk printing of the same design on bags or backpacks, as well as promotional items.

Pros: Cost-efficient for high-volume orders, wide color versatility, and excellent durability.

Cons: Not suitable for small batches or intricate, multi-color designs.

2. DIRECT TO GARMENT (DTG)

How it works

DTG employs inkjet technology to print designs directly onto fabrics. This allows for precise, high-resolution images with complex details.

Best for

Small businesses or individuals requiring small runs or detailed, custom artwork.

Pros: No minimum order quantity, vivid and detailed prints, adaptable to different color bases.

Cons: Higher cost for large-scale production, slightly less durable than traditional methods.

3. SUBLIMATION

How it works

Sublimation uses heat to turn dye into gas, which then bonds with polyester surfaces, producing seamless and vibrant images.

Best for

Polyester bags or backpacks requiring full-color, photo-quality designs.

Pros: Long-lasting, fade-resistant prints with no extra texture.

Cons: Limited to polyester materials and requires specialized equipment.

4. HEAT TRANSFER

How it works

Designs are printed onto transfer paper and then applied to the product using heat and pressure.

Best for

Small orders or designs with gradients and multiple colors.

Pros: Great for detailed designs, budget-friendly for small runs, easy customization.

Cons: Less durable over time; may peel or crack with heavy use.

5. EMBROIDERY

How it works

Embroidery stitches patterns or logos directly into the fabric using high-precision machines.

Best for

Brands wanting a premium and timeless look on their bags and backpacks.

Pros: High-end aesthetic, long-lasting quality, suitable for most fabric types.

Cons: Not ideal for fine, complex artwork and can be costly.

6. FOIL PRINTING

How it works

Foil is heat-pressed onto the material to create metallic or reflective finishes.

Best for

Luxury branding or products designed to stand out with a metallic sheen.

Pros: Distinctive, high-end appearance with a variety of foil colors.

Cons: Limited compatibility with materials and higher cost for large-scale designs.

7. EMBOSSING

How it works

Embossing raises designs above the surface by applying pressure from below, creating a 3D effect.

Best for

Brands aiming for a sophisticated, tactile look for their logos or patterns.

Pros: Premium feel, durable, and visually striking.

Cons: Works best with simple designs; higher setup cost.

8. DEBOSSING

How it works

The reverse of embossing, debossing presses the design into the surface, creating an indented effect.

Best for

Brands wanting a subtle yet classy finish.

Pros: Minimalist and refined appearance, long-lasting.

Cons: Limited to simple shapes or patterns, with higher costs.

9. UV PRINTING

How it works

UV light instantly cures the ink during printing, resulting in sharp, high-resolution designs.

Best for

Fast production runs requiring detailed and vibrant prints.

Pros: Quick turnaround, eco-friendly, high precision.

Cons: Limited material compatibility and higher setup costs.

10. FLOCK PRINTING

How it works

Flock printing uses adhesive and tiny fibers to create soft, velvety textures on surfaces.

Best for

Unique, tactile branding or decorative elements.

Pros: Adds texture and uniqueness, available in various colors.

Cons: Limited material use and higher costs for detailed designs.

How to Select the Right Printing Method

When choosing a branding technique for bags or backpacks, consider: