Blog

Foam Mesh Fabric: An In-Depth Guide

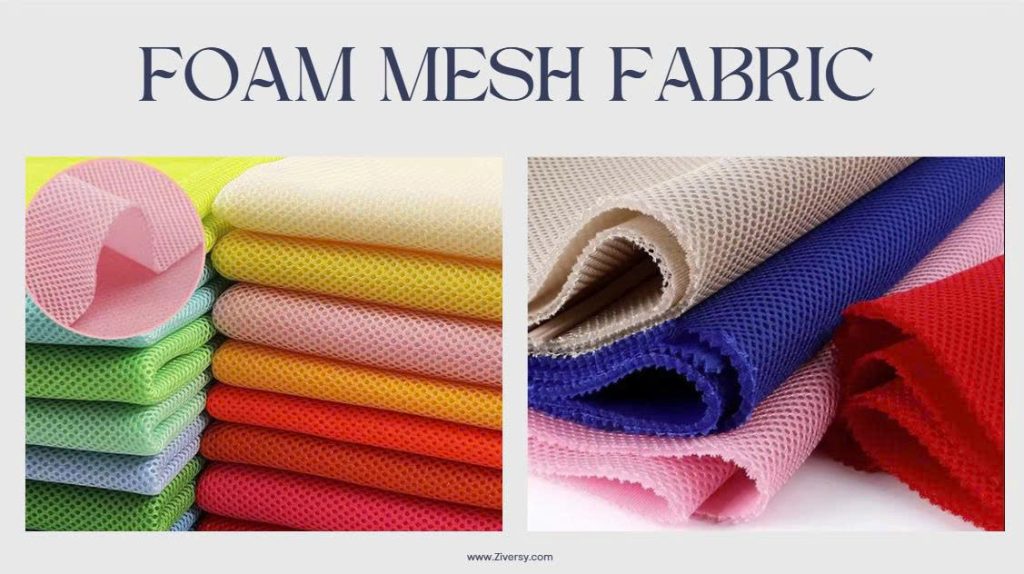

Foam mesh fabric is transforming the textile and apparel sectors with its unique blend of breathability and lightweight performance. This modern material has gained traction in everything from sportswear and uniforms to high-fashion pieces and sustainable clothing collections. But what exactly sets foam mesh apart? And how can brands and suppliers use it to remain competitive?

One standout variation—foam sandwich mesh—is especially versatile, serving roles in spacers, ventilators, and as linings for bags, seating, and cushioning.

In this guide, we’ll break down what foam mesh fabric is, its main features, benefits, types, and innovations—plus how it’s being applied in real-world manufacturing. Whether you’re a garment producer looking for performance fabrics or a textile trader expanding your catalog, this resource will help you make informed decisions.

What is Foam Mesh Fabric?

Foam mesh fabric is a specialty textile recognized for its porous, breathable design. Typically made from polyester, nylon, or other synthetic fibers, it allows consistent air circulation while maintaining durability. Within this category, foam sandwich mesh stands out as a multifunctional option used in industries from fashion to automotive.

Core Properties of Foam Mesh

Practical Applications

Advantages in Apparel Production

Different Types of Foam Mesh

Innovations Shaping Foam Mesh

Sourcing Foam Mesh Fabric

When sourcing foam mesh, textile wholesalers and manufacturers should consider more than just price:

Quality Checkpoints

Case Studies

- 1Sportswear Brand – Increased sales by 25% after switching to breathable foam mesh jerseys.

- 2Eco Label – Cut carbon emissions by 20% with recycled mesh fabrics.

- 3Uniform Maker – Improved comfort for healthcare uniforms by 30%, securing long-term contracts.

- 4Fashion Designer – Gained industry buzz with avant-garde runway looks using foam mesh textures.

Looking Ahead: Foam Mesh and Sustainable Fashion

With sustainability becoming a global priority, foam mesh is set to play a major role. New advances—like plant-based polymers and circular production—could further expand its applications in both fashion and beyond.

Conclusion

Foam mesh fabric is far more than a technical textile—it’s a versatile, cost-efficient, and increasingly sustainable material shaping the future of fashion and manufacturing. Its combination of breathability, strength, and adaptability makes it a reliable choice across multiple industries, from apparel to furniture.

Ready to explore foam mesh for your next project? Reach out to our team of specialists today and discover the possibilities.