Blog

Mesh Waterproof Fabric by the Yard: A Complete Guide for Manufacturers and Traders

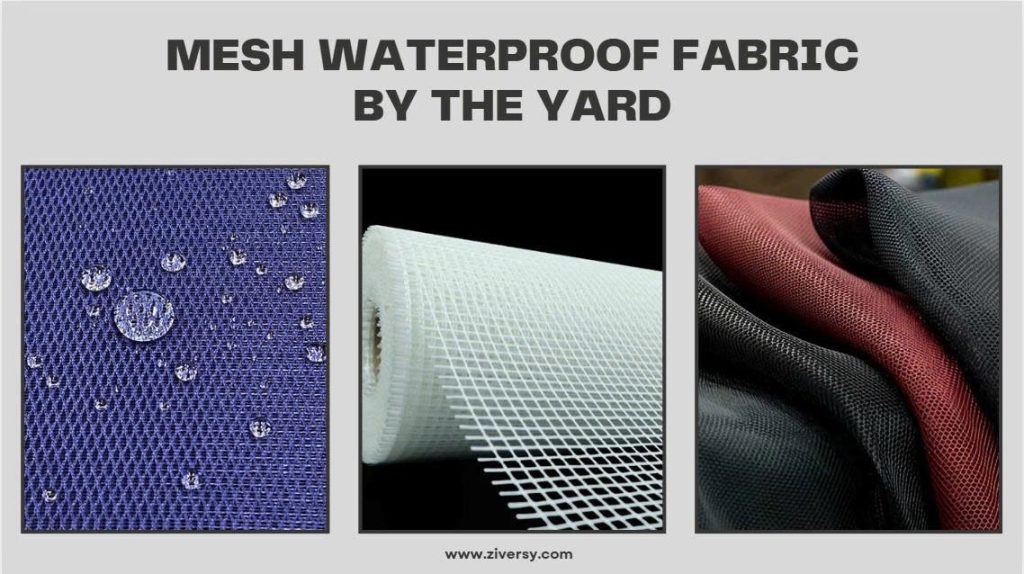

Mesh waterproof fabric has become a groundbreaking material across multiple industries—from garment manufacturing to outdoor equipment production. Whether used for crafting durable backpacks or breathable rainwear, this fabric provides an exceptional balance of strength, water resistance, and ventilation. Its adaptability makes it a go-to choice for various applications, especially in outdoor products designed for activities such as hiking, camping, or adventure travel.

This comprehensive guide covers everything about mesh waterproof fabric by the yard—its composition, variations, benefits, sourcing insights, and essential maintenance practices.

Understanding Mesh Waterproof Fabric

What is Mesh Waterproof Fabric?

Mesh waterproof fabric is a unique textile that blends a porous mesh construction with advanced waterproof coating technology. It’s usually made from synthetic fibers like nylon or polyester, coated with PU (polyurethane) or TPU (thermoplastic polyurethane) to enhance resistance against water. The result is a fabric that’s lightweight, flexible, and capable of repelling moisture while maintaining breathability. These properties make it highly suitable for outdoor and performance-based uses where durability and comfort are equally important.

What is Mesh Fabric?

Mesh fabric itself is a material characterized by an open-knit or woven pattern that promotes airflow and ventilation. Generally produced from synthetic materials such as polyester or nylon, it’s recognized for its durability, wrinkle resistance, and quick-drying ability. Because of these advantages, mesh fabric is a staple in sportswear, footwear, outdoor accessories, and technical garments, providing comfort and practicality in dynamic environments.

Importance Across Industries

Mesh waterproof fabric isn’t just practical—it’s also a foundation for design innovation. With polyester and nylon options meeting international standards such as ANSI, ASTM, and AATCC, it supports both industrial and consumer-grade applications.

A Brief History of Mesh Fabrics

While early versions of mesh fabrics can be traced back to ancient handwoven textiles, their modern form emerged in the late 19th century with the creation of synthetic fibers. Initially crafted from cotton, mesh fabrics gained widespread popularity after polyester and nylon were introduced, offering superior strength, elasticity, and resistance to environmental wear. Over time, their functionality expanded—making them indispensable in industries ranging from fashion and automotive to industrial and outdoor gear.

Types of Mesh Waterproof Fabric

1. Heavy-Duty Outdoor Nylon Mesh

2. Lightweight Waterproof Netting Fabric

3. Breathable Waterproof Mesh for Activewear

How It’s Made

The production of mesh waterproof fabric begins with creating synthetic fibers such as polyester or nylon, which are then spun into yarn. Using specialized techniques like warp knitting or circular knitting, the yarn forms a mesh structure with open spaces. Once the base fabric is produced, it undergoes finishing processes such as dyeing, coating, or lamination—where waterproofing layers like PU or TPU are applied. These treatments enhance both performance and longevity, ensuring that the final product meets rigorous industry standards.

Key Benefits and Common Applications

Core Advantages:

Applications in Practice:

Why Polyester Mesh Stands Out

Among the available materials, polyester mesh remains a top favorite due to its combination of light weight, breathability, and moisture control. It keeps wearers cool and dry, resists wrinkles, and maintains its shape through repeated use. Its easy maintenance and resilience have made it a top choice in sectors such as athletic wear, outerwear, and industrial fabrics.

Sourcing and Buying Mesh Waterproof Fabric

Where to Purchase:

Buying Tips:

Wholesale Options:

Purchasing in bulk allows cost efficiency and color consistency. Suppliers often stock mesh fabrics in various densities and finishes, ideal for large-scale apparel or gear manufacturing.

Care and Maintenance

Cleaning:

Storage:

Proper care ensures that the fabric’s waterproof and structural qualities remain intact over time.

Bringing Innovation to Every Project

Mesh waterproof fabric by the yard is more than a textile—it’s an enabler of durability, performance, and creativity. From outdoor jackets to industrial equipment covers, its applications are nearly endless.

For manufacturers, traders, and designers seeking to innovate with reliable and adaptable materials, this fabric represents a smart, forward-thinking choice. With the right sourcing and handling, mesh waterproof fabric can elevate your products to new levels of functionality and appeal.