Blog

What Is The Difference Between Nylon and Polyester Fabric?

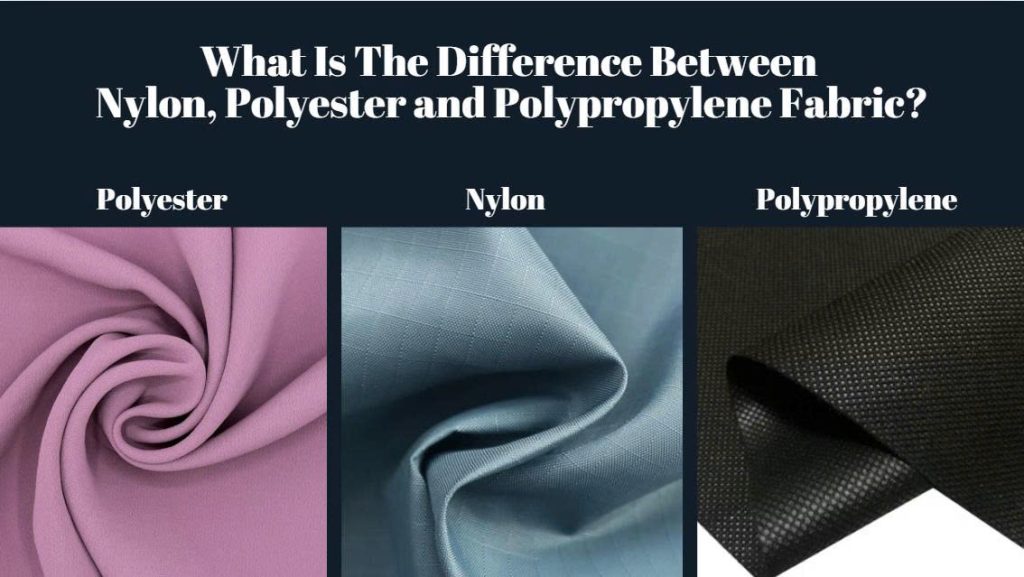

When sourcing fabrics as a buyer or wholesaler, understanding the unique properties of each material is crucial to making the right choice. Among the most widely used synthetic fabrics are polyester, nylon, and polypropylene. Each fabric offers distinct characteristics, strengths, and weaknesses, making them suitable for specific applications.

In this guide, we will explore their similarities, differences, advantages, disadvantages, and provide tips on choosing the right fabric. We’ll also highlight where to source high-quality bulk fabrics from China, the world’s largest textile hub.

What Are Synthetic Fibers?

Synthetic fibers are man-made materials derived from chemical compounds, commonly petroleum-based. Produced through an extrusion process, these fibers are melted, drawn into thin strands, and engineered with specific performance attributes.

Thanks to their durability, versatility, and cost-effectiveness, synthetic fibers dominate both everyday clothing and specialized textiles, from sportswear to industrial materials.

Polyester and Nylon: Definitions and Origins

Both fibers were introduced in the mid-20th century and have since become industry staples.

A Brief History of Synthetic Fibers

The journey of synthetic fibers began in the early 20th century:

Similarities Among Polyester, Nylon, and Polypropylene

These three synthetic fabrics share several key attributes:

Key Differences Between Polyester, Nylon, and Polypropylene

1. Polyester

Features:

Uses: Sportswear, casual wear, home furnishings, packaging materials.

2. Nylon

Features:

Uses: Outdoor equipment, hosiery, luggage, activewear, automotive components.

3. Polypropylene

Features:

Uses: Non-woven medical textiles, food packaging, marine ropes, outdoor furniture.

Blended Fabrics: Pros and Cons

Polyester-nylon blends combine the advantages of both fibers:

How to Identify Each Fabric

Choosing the Right Fabric

End Use:

Budget: Polyester is generally the most cost-effective option, while nylon is priced higher due to its properties.

Eco-Friendliness: Look for recyclable fabrics or eco-finishes for a sustainable choice.

Final Thoughts

Understanding the differences between polyester, nylon, and polypropylene is essential for making strategic purchasing decisions. By working with reputable suppliers and selecting fabrics based on your specific needs, you can deliver high-quality products that resonate with your customers.