Blog

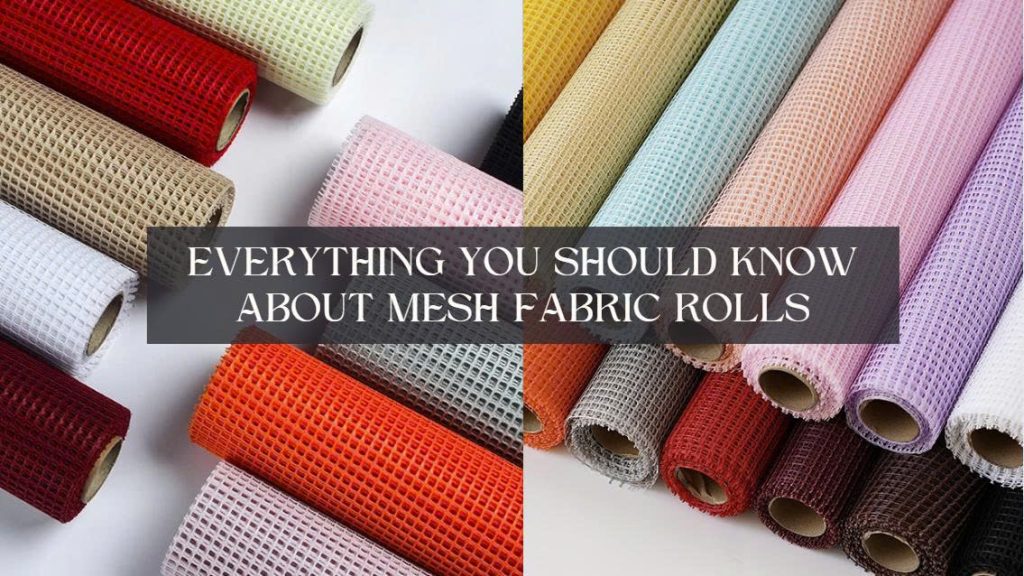

Everything You Should Know About Mesh Fabric Rolls

Mesh fabric rolls have become a vital resource across numerous industries—from apparel and textiles to activewear and industrial applications. Valued for their lightweight strength, breathability, and adaptability, mesh fabrics deliver unmatched performance, making them a go-to material for many manufacturing and design needs. Typically sold in continuous yard rolls, mesh fabric provides seamless lengths ideal for production efficiency and creative flexibility.

If you’re a garment manufacturer, textile distributor, or workwear designer, this guide will help you understand the uses, benefits, selection criteria, and future trends shaping the world of mesh fabric rolls.

What Is a Mesh Fabric Roll?

A mesh fabric roll is composed of interlaced, high-tensile fibers that form a net-like structure with open holes. This design enhances airflow, flexibility, and strength, making it ideal for both fashion and functional purposes. Mesh fabrics are commonly made from polyester, nylon, or cotton, depending on the desired texture, performance, and durability.

Supplied in rolls for easy storage and mass production, mesh fabrics are widely used in clothing, upholstery, outdoor equipment, and protective gear.

Key Properties and Benefits

Mesh fabric rolls combine practicality and performance in one material. Here are their standout features:

Types of Mesh Fabric Rolls

Mesh fabric rolls come in various types, each with distinct advantages:

Mesh fabrics also differ in weave density—tighter weaves offer greater strength and less transparency, while looser ones provide better ventilation for sportswear and casual garments.

Applications Across Industries

1. Garment Manufacturing

Mesh fabrics are commonly used to enhance clothing comfort, style, and function. They’re often featured in:

2. Sportswear and Performance Gear

Athletic brands rely heavily on mesh fabrics for their moisture control and ventilation. Common uses include:

3. Workwear and Safety Apparel

Mesh is widely used in high-visibility vests, gloves, and protective uniforms, offering comfort without sacrificing safety. It’s also found in pool covers and outdoor barriers where airflow and strength are needed.

Main Benefits at a Glance

How to Choose the Right Mesh Fabric Roll

Choosing the right mesh fabric depends on your intended use and production goals. Consider these factors:

1. Material, Weave, and Width

For high-strength needs, pick tighter weaves. For maximum airflow, choose looser ones.

2. Color and Customization

Mesh rolls are available in neutral or vibrant tones, with printing options such as heat-transfer and direct dyeing. These methods maintain flexibility and ensure vivid, lasting color.

3. Supplier Reliability

Partnering with trusted suppliers ensures consistent quality. Certifications like OEKO-TEX® guarantee eco-friendly and safe materials—crucial for sustainable manufacturing.

Care and Maintenance Tips

Proper handling helps maintain mesh fabric’s performance:

Well-maintained mesh rolls retain their appearance, elasticity, and strength for longer.

DIY and Creative Applications

Mesh fabric is beloved by DIY enthusiasts and crafters. It’s great for:

When buying mesh rolls, note that they’re usually sold in continuous yards—for example, a 10-yard roll means one seamless piece. This is ideal for large, uninterrupted projects.

Crafting techniques like the curl or pouf method can be used to shape and style mesh into creative, three-dimensional designs.

Real-World Success Stories

Future Trends

Why Mesh Fabric Rolls Matter for Your Business

Mesh fabric rolls offer functionality, creativity, and performance—a combination that gives your brand an edge. Whether for fashion, sportswear, or industrial gear, mesh fabrics help you innovate, scale, and deliver quality.

Ready to take your next project to the next level? Partner with our team to find the perfect mesh fabric roll tailored to your production and design needs.